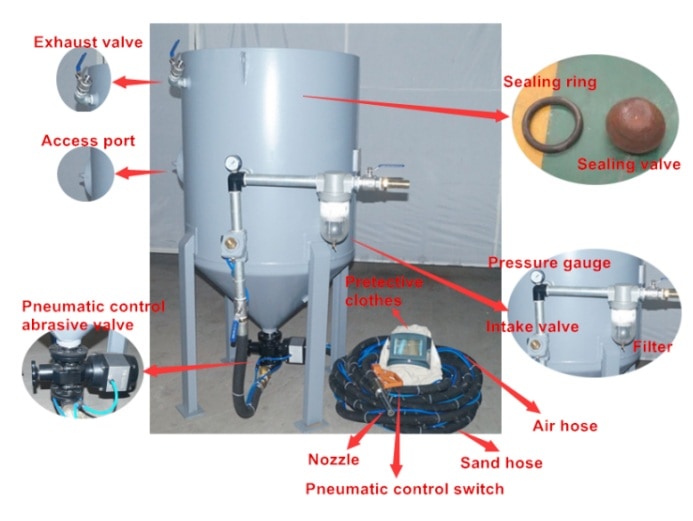

pneumatic air sandblast pot

- specifications

- feature

- application

- contents

- download

- comments

FB specializes in portable air blast pot used for blasting, cleaning, corrosion control, and surface preparation. FB product line includes standard sandblast machines, blast nozzles, couplings, hose, blast respirators, operator safety and comfort systems, and specialty blast tools.

The pressure vessel stays pressurized until manually depressurizing. Keeping the blast pot under constant pressure helps reduce high volume usage of air and wear & tear on the air compressor, also media costs are proven to go down.

This blasting pot is user friendly and inexpensive to maintain and operate

Tank Diameter Ø800mm

Tank Height 1550mm

Tank Volume 0.5m³

Continuous Blasting Time per Fill About 25mins

Weight (approximately) 250kg

Working Pressure 0.4~0.7MPa

Blast Gun 2pcs

Nozzle Boron Carbide; diameter 5/16’’(8mm)

Blasting Hose Diameter 1’’(40mm), length 30’(15m)

Air Compressor Requirement 37kw, 0.7-1.2Mpa (air consumption 6.2m³/min)

Air hose Blue; DN25

Abrasive Capacity Steel Shot/Steel Grit/Silica; Less than 30 mesh

Warranty 1 year

1. A normally closed sandblast pot system designed for the glass etching/carving industry that enables the operator to have a quick on/off control at the nozzle.

2. The sandblast pot use Industrial-quality valves, piping and fittings designed to maximize air flow and minimize energy required to operate the system.

3. Abrasive valve maintains smooth, consistent, adjustable media flow.

4. One-man operated, portable design but with industrial-quality blast machines.

5. Small size in space occupation so as to reduce the transportation cost

Ideal for smaller blast cleaning jobs. Widely used in the automotive industry and in some industrial applications.

1 blast gun with nozzle and pneumatic control switch, one blast hose 40mm*15m with one air hose, one protective blast clothes.